业务咨询 Business hotline:+86 139 3797 2936

招聘咨询 Recruitment hotline:+86 166 3886 5850

地址:河南省洛阳市涧西区云杉路与兴业路交叉口

Address:Yunshan Road, Jianxi District, Luoyang City, Henan Province

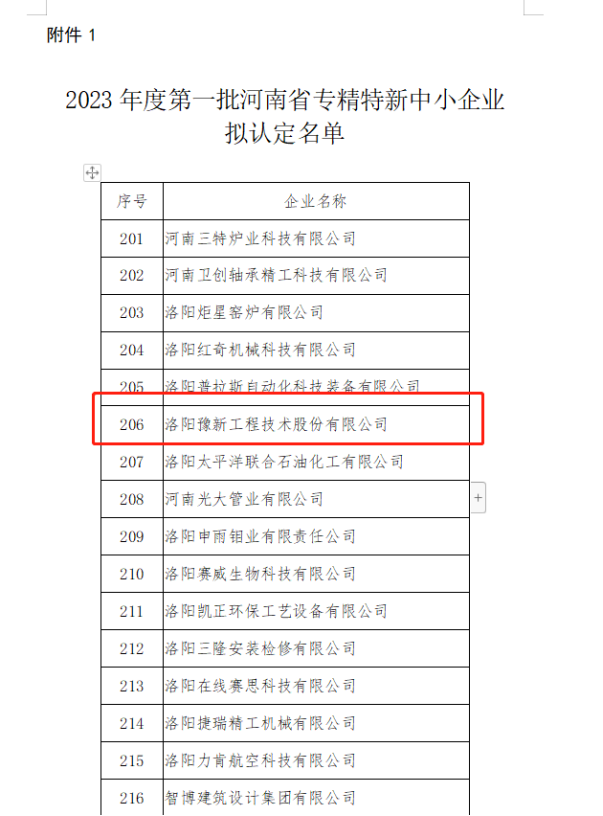

洛阳豫新工程技术股份有限公司位于以雄厚机械加工能力闻名全国的重工业城市——洛阳,工厂占地面积3.5万平方米,注册资本3000万元。公司拥有高素质团队及完善的组织架构,专注于非标准冶金设备的研发、设计、生产与销售,截至2025年,公司获得”洛阳市市级企业研发中心”“河南省专精特新”“洛阳市智能散料输送系统工程技术研究中心”“洛阳市高新技术企业”荣誉,拥有授权专利20余项,并通过ISO9001质量体系、职业健康管理体系、环境管理体系认证等。

公司的主导产品有废钢预热设备、钢(铁)水包(立/卧式)、中间包烘烤装置、浸入式水口烘烤装置、RH真空及合金烘烤炉、工业炉自动燃烧控制系统等,其中烘烤器系列产品融合国内外先进技术,1990年即通过冶金部鉴定。在智能控制方面应用PLC及人机界面控制系统,实现自动化操作与程序化检测控制,成功研发高效蓄热式烘烤装置,显著提升“节能、降耗、环保”性能。

公司建立严格的质量检测标准和先进设备,全程监控生产质量。凭借优质产品、可靠性能与完善服务,产品畅销全国,为武钢、马钢、太钢、攀钢等数十家大型钢铁企业提供了关键设备和成套解决方案(如钢包烘烤、中间包烘烤、矿用磨机、混铁炉等)。

洛阳豫新致力于为金属冶炼行业提供氧气在耐材烘烤及废钢预热环节的整体应用解决方案,打造技术一流的装置。

Luoyang Yuxin Engineering Technology Co. Ltd, is located in Luoyang, a heavy industrial city renowned for its strong mechanical processing, capablities. The factory covers an area of 35000 square meters and has a registered capital of 30 milion yuan, The company has a high-quality team and a complete organizational structure, focusing on the research and development, design, production, and sales of non-standard metallurgical equipment, As of 2025, the company has won honors such as "Luoyang City level Enterprise R&D Center", "Henan Province Specialized, Refined, and New". "Luoyang intelligent Bulk Material Conveyor System Engineering Technology Research Center", and "Luoyang High tech Enterprise", it has more than 20 authorized patents and has passed 1$09001 quality system, occupational health management system, environmental management system certification,etc.

The company's leading, products include scrap preheating equipment, steel (ironl water bags (vertical horizontal)intermediate bag baking devices, immersion water nozzle baking devices, RH vacuum and alloy baking ovens,industrial furnace automatic combustion control systems, etc, The baking,series products integrate advanced technologies from both domestic and foreign sources, and were appraised by the Ministry of Metallurgy in 1990,. in terms of intelligent control, PLC and human-machine interlace control system are applied to achieve automated operation and programmed detection and control An efficient heat storage baking device has been successfully developed, significantly improving, the performance of "energy saving.consumption reduction,and environmental protection".

The company establishes strict quality inspection standards and advanced equipment to monitor production quality throughout the entire process, With high-quality products, reliable performance, and comprehensive services, our products are sold well throughout the country, providing key equipment and complete solutions (such as ladle baking, intermediate ladle baking, mining,mills, mixed iron furnaces, etc,) for dozens of large steel enterprises such as Wuhan lron and Steel, Maanshan lron and Steel, Taiyuan lron and Steel, and Panzhihua lron and Steel.

Luoyang, Yuxin is committed to providing a comprehensive application solution for oxygen in refractory baking and scrap preheating for the metal smelting industry, and creating, a technologically advanced device.

1992年,在冶金行业成功研发应用首套燃气耐材烘烤设备工艺,实现包罐耐材高效均匀烘烤

2012年,在工业领域成功研发应用首套管状带式输送设备工艺,实现散装物料高效无尘输送

2015年,挂牌上市新三板

2016年,成功研发应用国内最大管径管状带式输送设备工艺

2018年,在冶金行业成功研发应用首套纯氧燃烧废钢预热设备工艺,现销售应用设备工艺每年再生再利用古铁废弃物450万吨,降低碳排放750万吨

2021年,在冶金行业成功研发应用首套纯氧燃烧耐材烘烤设备工艺,现销售应用设备工艺每年节省冶金行业能源耗量5亿平方

2024年,在有色行业成功研发应用首套氢能转化炉窑冶炼设备工艺,现销售应用设备工艺氢气完全替代天然气,每年节省20%生产成本

In 1992, the first set of gas refractory material baking equipment technology was successfully developed and applied in the metallurgical industry, achieving, eficient and uniform baking of refractory materials for ladle packaging

In 2012, the first sleeve shaped belt conveyor technology was successfully developed and applied in the industrial field,achievine efficient and dust-free transportation of bulk materials

In 2015, listed on the New Third Board

In 2016, we successfully developed and applied the process of the largest diameter tubular belt conveyor equipment in China

In 2018, we successfully developed and applied the first set of pure oxygen combustion scrap preheating equipment technology in the metallurgical industry. Currently, we sell and apply the equipment technology to regenerate and reuse 4.5 milion tons of ancient iron waste annually, reducing carbon emissions by 7.5 million tons

In 2021, the first set of pure oxygen combustion refractory material baking equipment technology was successfully developed and applied in the metallurgical industry. Currently, the sales and application of equipment technology save 500 million square meters of energy consumption in the metallurgical industry annually

In 2024, the first set of hydrogen conversion furnace smelting equipment technology was successfully developed and applied in the non-ferrous industry, Curently, the application equipment technology uses hydrogen gas to completely replace natural gas, saving 20% of production costs annually.