业务咨询 Business hotline:+86 139 3797 2936

招聘咨询 Recruitment hotline:+86 166 3886 5850

地址:河南省洛阳市涧西区云杉路与兴业路交叉口

Address:Yunshan Road, Jianxi District, Luoyang City, Henan Province

核心技术:环形集束燃烧器

Core Technology: Ring-shaped Jet Burner

国内在使用耐材烘烤设备热效率最高

秦皇岛宏兴钢铁150T钢包铁包

热值1000kcal 压力7kpa 转炉煤气

热值750Kcal 压力10Kpa 高炉煤气

烘烤4-8h 平均温度1000-1100℃ 温差小于50℃

The domestic use of refractory baking equipment has the highest thermal efficiency

Qinhuangdao Hongxing Steel 150T steel ladle iron ladle

Heat value 1000kcal Pressure 7kpa converter gas

Heat value 750Kcal Pressure 10Kpa blast furnace gas

Baking 4-8h Average temperature 1000-1100 ℃ temperature difference less than 50℃

核心技术:环形集束燃烧器

Core Technology: Ring-shaped Jet Burner

国内在使用耐材烘烤设备热效率最高

唐山天柱钢铁八机八流/六机六流中包热值 700Kcal 压力 10Kpa

高炉煤气耐材烘烤 120-180min 平均温度 1000-1100°C 温差小于50°C

The domestic use of refractory drying equipment has the highest thermal efficiency

Tangshan Tianzhu Steel eight-machine eight-stream/six-machine six-stream ladle heat value 700 Kcal pressure 10Kpa

blast furnace gas refractory baking 120-180min average temperature 1000-1100°C temperature difference less than 50°C

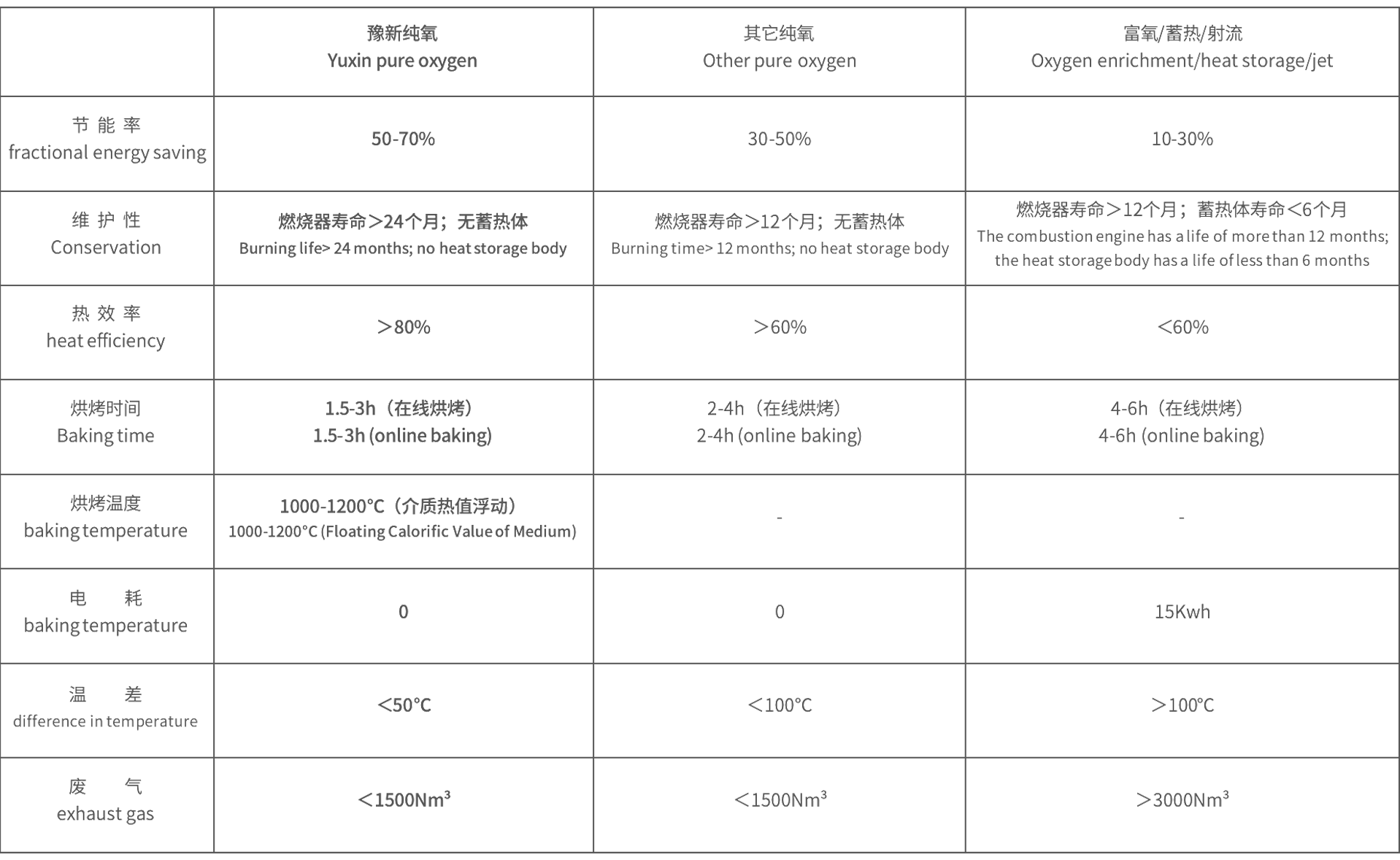

1.增加供氧阀站和煤气阀站;

2.增加纯氧燃烧系统及安全防护措施,确保其能够实现高效的燃烧,以实现精确控制和安全监测;

3.升级自动化控制系统,采用先进的控制算法和传感器技术,实现更加智能化燃烧过程管理,整套系统含机、电、仪一体化改造。

1.Add oxygen supply valve station and gas valve station;

2.Add pure oxygen combustion system and safety protection measures to ensure that it can achieve efficient combustion, so as to realize accurate control and safety monitoring;

3.Upgrade the automatic control system, adopt advanced control algorithm and sensor technology to realize more intelligent combustion process management, The whole system includes integrated transformation of machine, electricity and instrument.

周期为90天。包括:设计、生产、运输、指导安装调试,以及现场的技术培训。

纯氧钢包烘烤改造项目,充分考虑了与现有安全生产工艺、工序,厂区内的能源介质条件满足改造后的运行需求,与其他冶炼设备不存在冲突。

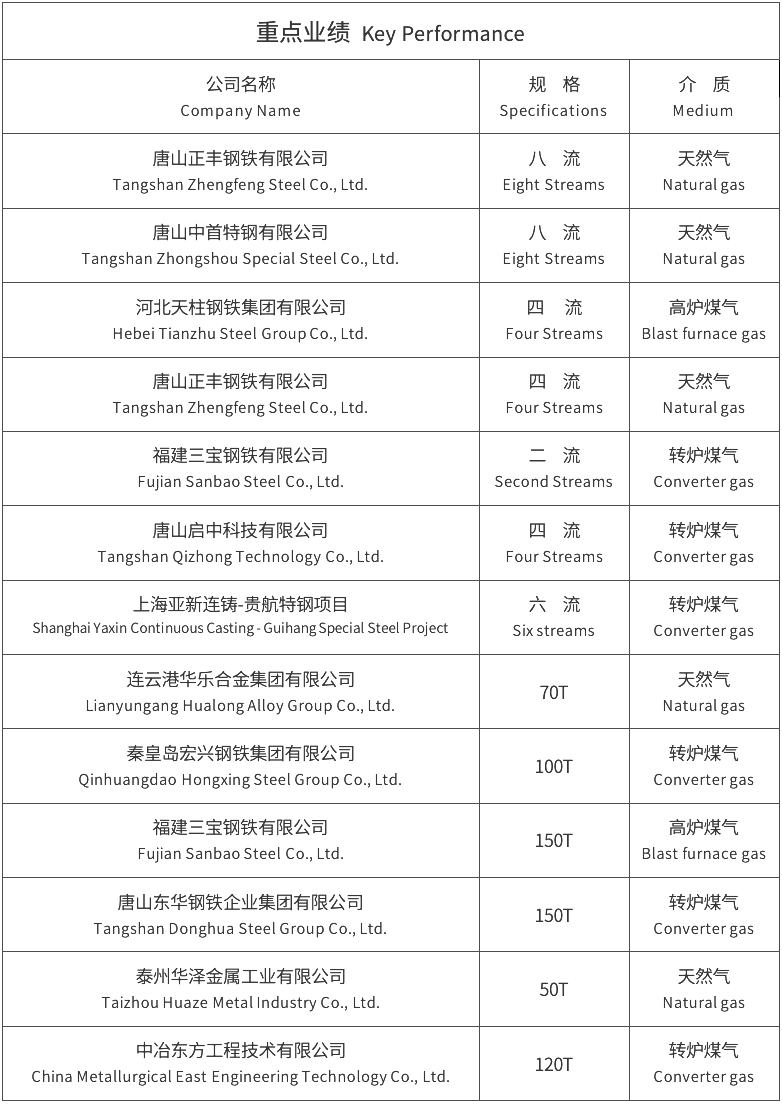

豫新自主研发的纯氧钢包烘烤系统基于过往丰富的热工与控制研发设计经验,已成功应用于众多大型钢铁企业,积累了丰富的行业应用实例。为确保项目改造的长期效益,公司承诺为后续运行、维护、设备升级提供持续的技术支持,确保客户的长期利益。

Project cycle 90 days, including design, production, ransportation, guidance of installation and commissioning, and on-site technical training.

The pure oxygen steel ladle baking renovation project fully considers the existing safety production process and process, the energy medium conditions in the plant to meet the operation requirements of the renovation, and does not conflict with other smelting equipment.

The pure oxygen ladle drying system independently developed by Yuxin is based on the past rich experience in thermal engineering and control R&D and design, has been successfully applied in many large steel enterprises, accumulating rich industry application examples. To ensure the long-term benefits of the project transformation, the company promises to provide continuous technical for subsequent operation, maintenance and equipment upgrading, so as to ensure the long-term interests of customers.